PostTime:8/16/2023

Realizing carbon peaking and carbon neutrality is a major strategic decision for countries around the world to respond to climate change and improve environmental health, and it is an extensive and profound economic and social systemic change. Among them, the new energy industry is an important pillar supporting the dual carbon goals. In 2022, the Chinese government released the "Implementation Plan on Promoting the High-Quality Development of New Energy in the New Era", proposing to increase policy support for cutting-edge technology innovation, increase investment in theoretical research, establish an industry-university-research integration platform, and lay out forward-looking, strategic and disruptive technological research in advance and other initiatives. Research in the field of new energy is entering accelerated development stage, and the fields of high-efficiency battery, hydrogen energy, and wind energy are the areas that receive the most global attention.

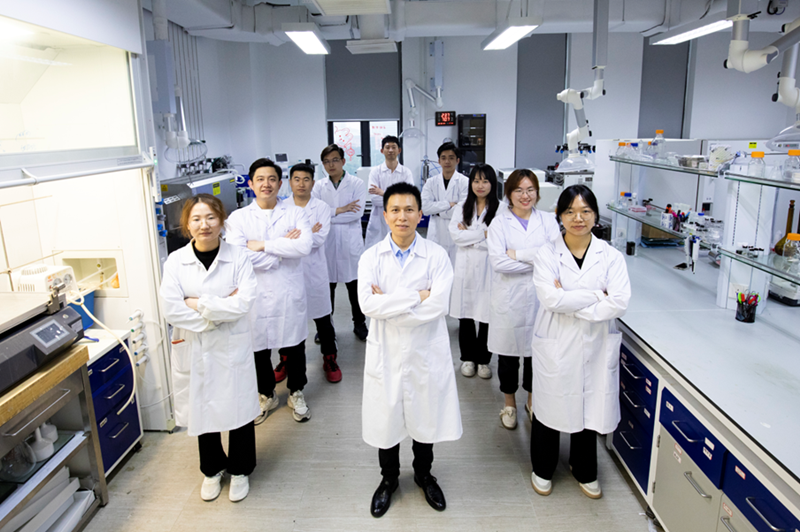

Guangdong Technion - Israel Institute of Technology (GTIIT) is committed to building a high-level international science and engineering research university, which has attracted a large number of high-level scholars to gather here to jointly promote innovative research, environmental protection and social prosperity. Among them, the research in the field of new energy has brought together a group of high-level scholars to create leading science and technology laboratories. At present, the overall layout has begun to take shape.

Battery Technology

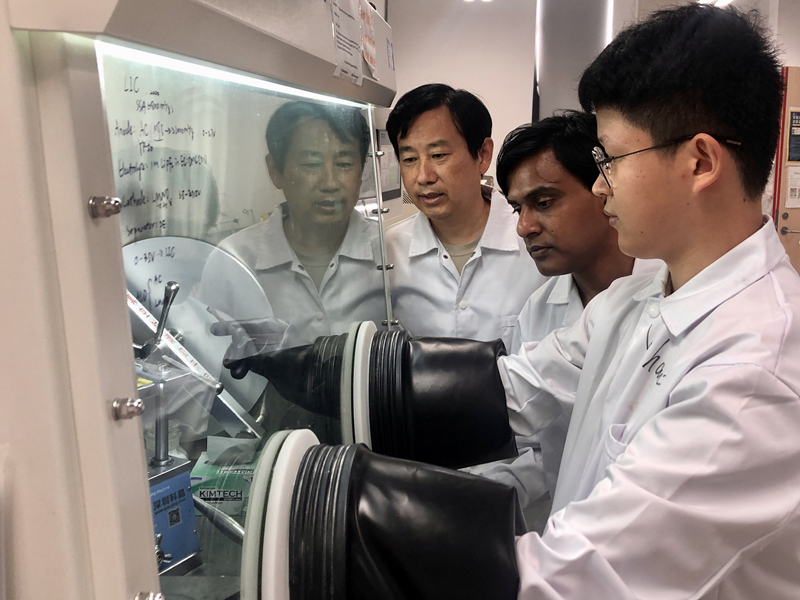

In the field of new energy storage capacitor and battery technology research, GTIIT Professor Daniel Tan from the Department of Materials Science and Engineering is committed to the research of electrostatic film capacitors and electrochemical supercapacitor materials. The team used atomic layer deposition technology to modify electrode materials such as commercial polymer films and activated carbon, which increased the working voltage by more than 30%, effectively improving the energy density and working temperature of the capacitor. The technology has been granted patents in China and the United States, and is cooperating with related companies for device testing, which has the potential for future industrialization. In terms of battery technology, the team conducts comprehensive research on lithium-ion and lithium metal battery electrodes and electrolyte materials. MOF is used to modify the lithium metal negative electrode to increase the melting rate of lithium, inhibit the growth of lithium dendrites, and improve the cycle stability of lithium metal batteries. At the same time, in the lithium battery electrolyte system, the team used appropriate additives to successfully develop a high-voltage stable lithium battery electrolyte above 5V, which effectively improved the energy density of the battery. At present, this technology has entered the patent application process.

In the field of rechargeable battery, GTIIT Associate Professor Yuanshen Qi from the Department of Materials Science and Engineering is specialized in battery pole piece processing and current collector processing. Through processing the pole pieces, the conductivity of the lithium iron phosphate positive pole piece and the high-nickel ternary positive pole piece has been improved by at least 20, thereby reducing the heating problem during battery discharge and improving the power performance of the battery. Now the project has completed the experimental stage, and has obtained an invention patent. It has great potential for future industrialization, and can be applied to lithium-ion and sodium-ion batteries.

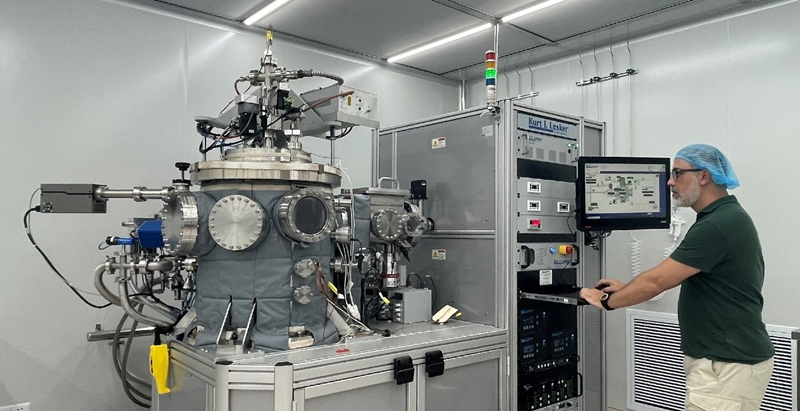

The application of new materials to the anode is another research idea. Silicon-based anodes are a promising alternative for current graphite anodes. However, due to huge volumetric changes via swelling-deswelling upon lithiation-delithiation cycling, the Coulombic efficiency of commonly proposed silicon-based anodes (even nanoparticulated ones) gradually decreases, and the anodes eventually break down. Professor Panagiotis Grammatikopoulos from the Department of Materials Science and Engineering of GTIIT has developed an approach that combines the advantages of nanoparticulated and coarser-scale systems, which is using gas-phase synthesis to intercalate metallic nanoparticles inside sculpted silicon thin films for lithium-ion battery anodes, to effectively solve the above problem.

In the field of lithium battery electrolytes, GTIIT Associate Professor Haijin Zhu from the Department of Materials Science and Engineering is committed to researching lithium battery electrolyte systems based on ionic liquids and polymer ionic liquids. Ionic liquids have the advantages of low vapor pressure, nonflammability and high ion conductivity, and can be used to replace traditional flammable organic solvents, and have broad application prospects in the field of electrochemical energy storage. Professor Zhu's team has made important progress in the design and synthesis of the chemical structure of ionic liquids and in the application of lithium-ion batteries, and has published more than 100 SCI papers in the area of electrolytes and fuel cells.

Ionogel electrolytes is an electrolyte that based on ionic liquids and gelling solid matrices, which offer several advantages for solid-state lithium batteries, including nonflammability, wide processing compatibility, and favorable electrochemical and thermal properties. GTIIT Associate Professor Woo Jin Hyun has developed novel ionogel electrolytes based on two-dimensional hydroxide nanosheets, which not only provides the fundamental understanding of unexplored interaction mechanism between hydroxide nanosheets and ionic liquids, but also allows to address traditional challenges (e.g., poor mechanical strength, low ionic conductivity and lithium transference number) of ionogel electrolytes for solid-state lithium battery applications. The ionogel electrolyte system will serve as an important platform to study interactions between solid matrices and ionic liquids, improve ionogel electrolyte properties, and develop high-performance solid-state lithium batteries.

In the field of large-scale research on lithium battery electrolytes, GTIIT Associate Professor Bo Kong from the Department of Chemical Engineering used advanced CFD modeling and simulation to study the crystallization process of lithium hexafluorophosphate/sodium hexafluorophosphate. It can carry out accurate and efficient numerical simulation of the crystallization process, realize reliable prediction of product characteristics such as flow field, temperature field, crystal size distribution and impurity content, and reveal the evolution mechanism of the complex flow field in the dynamic process through simulation analysis, thereby optimizing the morphology of the product and reducing impurities, finally it develops a dynamic crystallization process with high efficiency and energy saving to replace the traditional static crystallization process with huge energy consumption. The project team has collaborated with a domestic industry-leading company to carry out further research.

3D printing high-performance solid-state batteries is another hot research area. Dr. Vijaykumar Jadhav, a research scientist from Department of Materials Science and Engineering in GTIIT, aims to develop an ultra-small next generation of high-performance solid-state batteries. It includes alternative chemistries that are inherently safer to operate than aqueous lithium-based batteries, with high volumetric energy density and a stable long lifetime with a lightweight 3D-printed casing. Dr. Jadhav's research delivers advanced synthesis routes for flexible Nickel-Zinc electrodes for 3D-printed solid-state batteries, which have better operational and environmental stability (plastic rather than stainless steel) and safety, extended cycle-life, and wide temperature ranges of operation, and light weight. This low-cost, environmentally-friendly, and scalable method will yield the next generation of high-performance batteries, and has the power to seamlessly integrate a battery solution into any design of next generation personal or wearable technology, or any device or system that requires small volume power built into the physical device.

Hydrogen Technology

In the field of hydrogen energy, hydrogen production by catalytic conversion is an important research field. Among them, hydrogen production from plastic waste or biomass waste, which "turns waste into wealth", is an idea that has attracted wide attention. The team of GTIIT Associate Professor Xi Gao, Department of Chemical Engineering, prepared an iron oxide/alumina heterojunction composite material to replace the commonly used expensive pyrolysis catalyst noble metal ruthenium and platinum-based materials. The catalyst has high catalytic activity for plastic degradation and hydrogen production, and has good regeneration effect. At present, this research has obtained an invention patent. At the same time, the team developed a multiphase fluid dynamics model to design and optimize plastic and biomass hydrogen production equipment. The software has been released in the internationally renowned open-source fluid dynamics software MFIX.

Hydrogen separation is another significant field of hydrogen energy research. The high-efficiency membrane separation technology research by the team of GTIIT Associate Professor Xuezhong He from the Department of Chemical Engineering has important application potential in hydrogen energy transformation. In hydrogen production, membrane technology can be used for membrane separation and membrane reaction to achieve efficient hydrogen separation and purification. Gas separation membranes can extract high-purity hydrogen from complex gas mixtures; membrane reaction technology can realize highly selective generation of hydrogen in chemical reactions. Laboratory results have verified its good technical and economical properties. In addition to hydrogen production, efficient storage, distribution and utilization of hydrogen can also be achieved using membrane technology.

Wind Power Technology

In the field of wind power, the global construction of offshore wind farms has become a development hotspot in recent years. However, the scarcity of offshore measured data, high costs and difficulties of observation, and corrosion and aging of equipment are problems that need to be solved in this field. GTIIT Associate Professor Cheng Li from Department of Mechanical Engineering took the lead and joined hands with research teams from the Department of Mechanical Engineering, Department of Chemical Engineering, and the Department of Environmental Science and Engineering to undertake the project "Research on Optimizing Fan Control & Arrangement and Interface Protection New Technology Using UAV Measurements". Through research and development based on dynamic model and efficiency optimization control algorithm for the interaction between atmospheric turbulence and offshore wind farm based on measured data, research on the formation mechanism and protection of fouling on the surface of wind turbine structures and prediction models for wind turbine efficiency and fatigue life; it develops a high-precision multi-sensor UAV offshore wind power field data measurement platform, to improve the efficiency, stability and safety of offshore wind power projects.

The "Offshore Wind Power Corrosion Aging Intelligent Online Monitoring and Early Warning Protection System" project is led by GTIIT Associate Professor Zuoti Xie from Department of Materials Science and Engineering. It adopts self-developed long-distance (>20km) wireless transmission technology and is equipped with an intelligent corrosion monitor at the front end of the system, and the back end is connected to the data analysis platform to realize online corrosion monitoring. Through data analysis and intelligent control, the cathode potential is adjusted to achieve the protection purpose of inhibiting corrosion.

The above two projects have been approved for the 2022 Guangdong Provincial Science and Technology Innovation Strategic Special Project.

National Standard Formulation

It is worth mentioning that the research team of GTIIT also actively participates in the formulation of national standards and contributes wisdom to the development of the industry. Mr. Hongbo Xie, manager of the laboratory from Department of Materials Science and Engineering, participated in the formulation of SJ/T11889-2023, one of China's battery industry standards, as the main drafter. The rolling of pole pieces is a very important process in the production of lithium-ion batteries. This standard regulates the relevant requirements for rolling lithium-ion battery pole pieces, which is of great significance to the improvement of the product safety and quality of lithium-ion batteries. Mr. Xie has worked in BYD, Changhong Group and other companies, and has served as deputy director of R&D, chief engineer and other positions.

On the basis of first-class research teams and laboratories, the research strength in the field of new energy in GTIIT has been unanimously recognized by the industry, and the research team has reached a number of collaboration projects with the industry in this field. Looking forward to the future, GTIIT will further leverage its advantages in the field of new energy, promote the deep integration of discipline construction and industrial development, dig deep into the achievements of basic research, and actively explore industrial applications upward, so as to contribute to the dual carbon goals and net zero emissions, constructing a healthy society with GTIIT muscle!

For industry collaboration, please contact: gtec@gtiit.edu.cn

Text/Photos: GTEC, Wang Hui

© GUANGDONG TECHNION-ISRAEL INSTITUTE OF TECHNOLOGY | 粤ICP备17036470号