PostTime:6/24/2021

This summer, the first cohort students will graduate from Guangdong Technion-Israel Institute of Technology. Different from traditional graduation gift such as souvenir books and bags with university logo, GTIIT has prepared a special ring for its graduates. The ring is made of 3D printing technology and each ring has different student number on the inner circle. Each one is unique in the world.

How was this unique ring born? Let’s take a look!

Genesis: Search for the gift that has GTIIT style

At the beginning of this semester, the university began to prepare for the first graduation ceremony. Graduation gifts is one of the important step of the preparation. After many times of discussion, the university had a consensus on graduation gift:

(1) It is a graduation gift that can represent GTIIT.

(2) It is a graduation gift from a science and engineering university, which must contain scienific and technological elements.

(3) It is a graduation gift from a China-Israel cooperative university so it had better make with the technology of China-Israel cooperation.

(4) It is a graduation gift for students so it should contain students’ participation and recognition.

After many times of comparison, the university finally selected the ring as the graduation gift.

Design: Industrial Design Center, School of Art, Shantou University

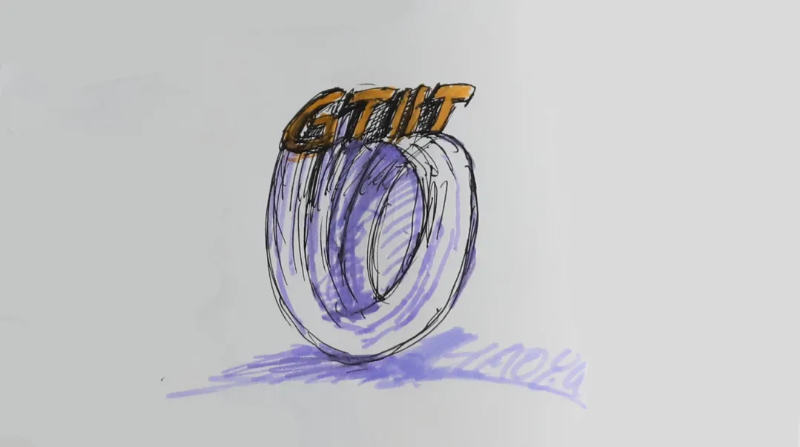

This is the office of Mr Li Haoyu and also the place where the design diagram of the ring was born. Mr Li Haoyu showed us the design sketch of the ring and introduced the design principles of it.

The ring shape was inspired by the “Fibonacci spiral”, which is a spiral curve drawn based on the Fionacci sequence. This shape contains profound mathematical principles. Starting from a single point, the five letters of GTIIT spiral upward, continously strech and rotate, and the arc changes from small to large, extending a “GTIIT shape” section. This rising process symbolizes the growth process of GTIIT and emphasizes the visibility of the process.

“The concrete design of GTIIT development process matches the internet thinking, that is, from reading text to reading symbols.” Mr Li told us. This ring is made of stainless steel because compared with other metals, steel is associated with science and future. So this metal is more in line with GTIIT’s features of focusing on science and technology and continuously pursuing innovation and development.

Design is a process of modification and improvement and from the design drawing to the final product, it requires constant trial and adjustment.

Location: Shantou Ruixiang Mould Co.,Ltd.

Walking into the laboratory, the first thing that caught your eye was the 3D printing equipment that is as tall as a person. “This machine can print 54 rings each time. It takes 45 hours. Each ring can be customized in size.” Said Zhang Qiujuan, executive director of Shantou Ruixing Mould Co., Ltd..

This 3D Printing Laboratory was established in 2017 due to the cooperation with Israel Aerospace Industries (IAI). It has been using 3D printing technology for the production and R&D of IAI aircraft parts. This time, these equipment and staffs “make little use of great talent” to produce GTIIT’s graduation rings.

Compared with traditional casting methods, 3D printing saves costs and time of mode making, and the production method is more flexible and personalized, so that the number is no longer a production limitation. Just use computer to model the ring, add the support structure and import it into the 3D printing equipment, and combine the rings of different sizes, and the equipment will carry out mass production according to the modelling form. With highly personalized features, people can try different design schemes in the same batch of products, it can help producers find the best choice more quickly.

Although the company has advanced technology and the experience of producing and developing precision parts for aviation and automobiles, the complicated design of the ring has caused a big difficulty for it. “Different from the overall mechanical properties such as density and hardness that need to be considered when making equipment accessories, making jewellery requires more consideration of beauty and exquisiteness.” Mrs Zhang Qiujuan explained. After 3D printing, the ring is not a finished product, but a semi-finished product wrapped with supporting material. How to perfectly remove the supporting structure without damaging the structure of the ring has became a major problem in the production process.

In order to present the perfect rings to the graduates, the designers and production staffs have gone through countless attempts and adjustments, and finally confirmed the production process of the rings. After the 3D printing, the rings need to undergo cutting-de-support-nitriding (reducing hardness)-electrolysis (to make the indentation as smooth as possible)-grinding-polishing-laser engrain. Assuming that all steps are going well, this process also took 5-6 days.

Some graduates also participated in the process of cutting and preliminary polishing process. Under the guidance of professionals, students put on gloves and used pliers and sandpaper of different meshes to polish the rings as close to the finished products as possible. This activity showed the strong hands-on ability of GTIIT students. "We all know that GTIIT students have a wealth of academic knowledge, but I didn't expect that even their hands-on skills are incredible."said Mrs Zhang.

From the thoughts to the complete design drawings; from stainless steel materials to finished products, this ring represent GTIIT’s best wishes for the first cohort of "children". GTIIT hopes all graduates will have a better future with the spirit of GTIIT.

What else is in the graduation gift package? Next time we will continue to tell you…

——TO BE CONTINUED——

© GUANGDONG TECHNION-ISRAEL INSTITUTE OF TECHNOLOGY | 粤ICP备17036470号